Reactors and SMRs

Nuclear energy provides a clean, emission-free source of electricity all day, every day.

How a Nuclear Reactor Works

Nuclear reactors produce heat by splitting atoms. That heat converts water into steam. That steam turns a turbine that spins a magnet which makes electricity flow to the grid.

Small Modular Reactors (SMRs)

Small modular reactors (SMRs) generate between 10 and 300 MWe and are much smaller than Canada’s flagship CANDU reactors, which average around 700 MWe.

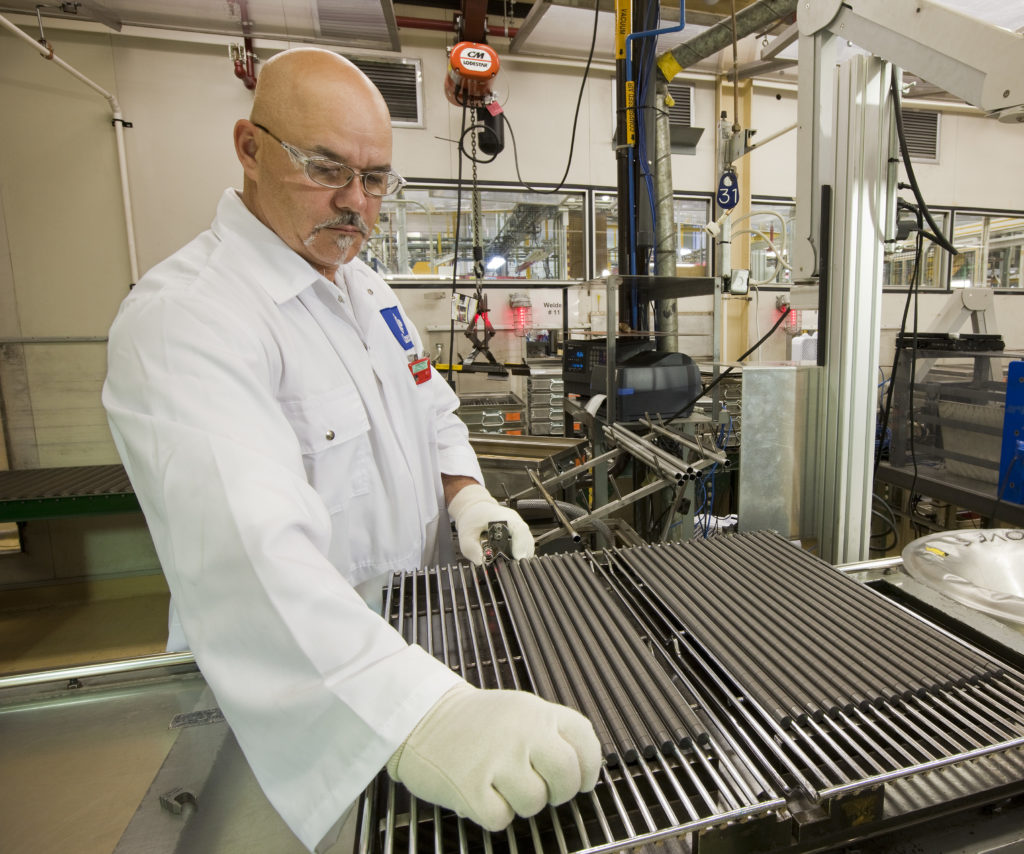

Nuclear Fuel

Nuclear fuel is very energy dense, so a nuclear reactor needs very little fuel. Uranium pellets weigh about 20 grams each (a little less than the weight of a AA battery).

Nuclear Power in Canada

Nuclear plants have been powering Canadian grids since the 1960s, but Canada has been involved in nuclear science and technology from the beginning.

Safety

The Canadian nuclear industry is one of the most closely monitored industries in the world. Major nuclear facilities are the most protected critical infrastructure in Canada.

Spent Fuel and Nuclear Byproducts

Spent fuel — the uranium that has powered nuclear reactors — makes up about three per cent of the volume of nuclear waste worldwide. The total amount of spent fuel bundles in Canada would fill about six hockey rinks to the height of the boards.