Canadian technology to play a key role in recycling of nuclear fuel

Many people are surprised to learn that nuclear power is a clean source of energy. It’s one of the lowest producers of greenhouse gases – even better than solar power, over its whole fuel cycle – and it produces far smaller volumes of pollutants than oil, coal or gas do. And the volume of waste is a tiny fraction of what coal-fired power plants would produce because uranium is extremely energy dense.

But there is always room for improvement. Montreal-based SNC-Lavalin is now taking steps to reduce that waste even more, through use of recycled uranium in its new Advanced Fuel CANDU Reactor (AFCR™), now being jointly developed with Chinese involvement.

Conventional recycling

Recycling nuclear fuel isn’t new. “When fuel comes from a Light Water Reactor, it can be processed, as is done in the UK, France and other countries,” explains Sermet Kuran, SNC-Lavalin’s Vice-President for the AFCR. More than 95% of the recycling output is recycled uranium that can be enriched and used again in light water reactors, but the process is costly, in money, electricity and environmental impact.

The Advanced Fuel CANDU Reactor

SNC-Lavalin’s AFCR design makes the use of recycled uranium more efficient, and China is a great place to start. China has a large number of Light Water Reactors, which use enriched uranium: this has a high percentage of uranium-235, the type of uranium that produces energy.

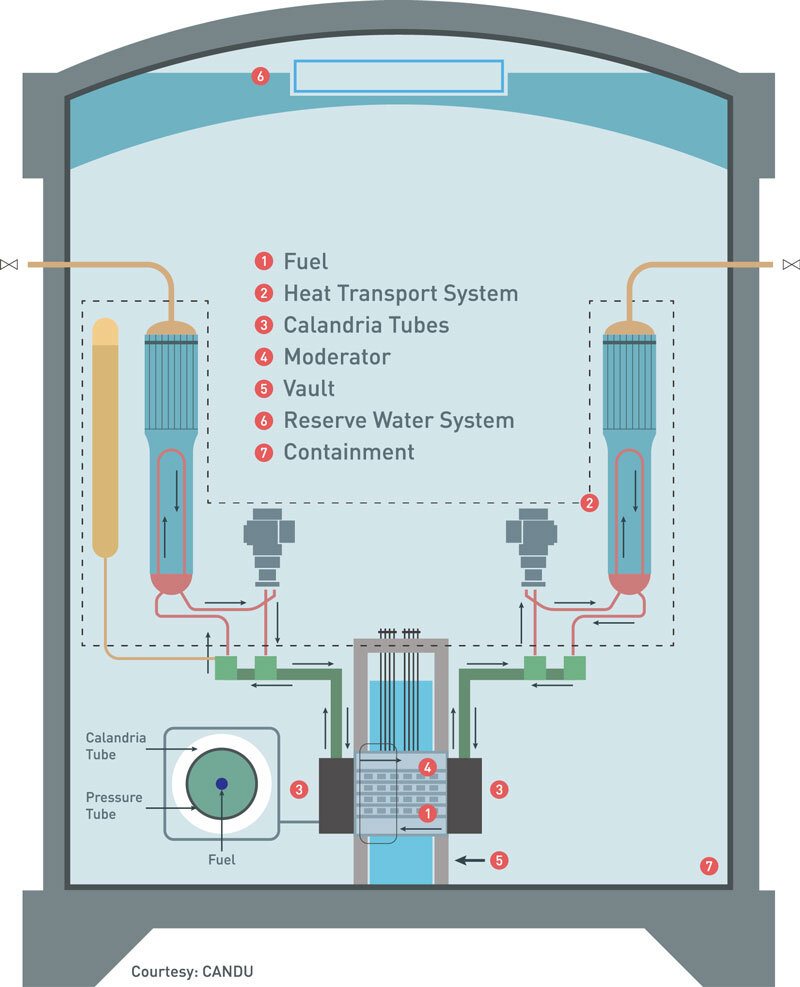

But the flagship Canadian design for power reactors, called CANDU, uses natural uranium, which has a much lower percentage of uranium-235. The AFCR is modified from the traditional design of CANDU reactors to accept recycled uranium directly in a way that doesn’t require enriching first. This makes recycling more economical.

This solution is particularly good for use in China, says Kuran. “Four Light Water Reactors can create the fuel to feed one of our AFCRs. China has about 30 reactors now, and they plan for about 100 of them.” They also import most of their uranium so this allows them to maximize the energy extraction.

Looking ahead

The AFCR has all the world-leading safety features already found in the CANDU reactors and is complemented by new active and passive safety features. Still, you won’t see an AFCR in Canada soon, says Kuran. “CANDU reactors already use uranium with about 30% more efficiency than any other reactors. So, the fissile material in our used fuel is low.” In other words, there isn’t enough uranium-235 left in Canadian used fuel for recycling to make economic sense here.

But it does make sense in China, where SNC-Lavalin plans to roll out the design gradually, to ensure that that the project runs smoothly. It’s an unprecedented opportunity: by piloting the AFCR, China saves money and energy, while a Canadian company takes on a key role in a growing market.