Risk and Large Infrastructure Projects

May 2015

The Ontario government has decided that refurbishing 10 of the province’s 18 nuclear reactors is the best plan to ensure affordable and reliable electricity for decades to come. That’s largely because carbon-free nuclear electricity will still be less expensive than solar, wind, or gas – even with the cost of refurbishment factored in.

The Ontario government has decided that refurbishing 10 of the province’s 18 nuclear reactors is the best plan to ensure affordable and reliable electricity for decades to come. That’s largely because carbon-free nuclear electricity will still be less expensive than solar, wind, or gas – even with the cost of refurbishment factored in.

But opponents of the project ask: How much will that refurbishment really cost? Their concerns are founded on cost overruns in past refurbishment projects – and the fact that large infrastructure projects, from building bridges to hydro dams, have a tendency to run over budget.

However, a closer look at the causes of delays and budget overruns in such projects shows that the Ontario nuclear refurbishment is well positioned to finish on time and on budget.

The challenge of one-of-a-kind jobs

The challenge with many large infrastructure projects is their uniqueness, which can lend itself to complexity. While some projects take advantage of improvements in materials or technology, these same factors also require new designs, more training, and more coordination among the people involved. This can add cost and time.

But this is also an opportunity. By learning from experience and applying ingenuity, some infrastructure operations eventually become almost routine. For example, in 2014, the City of Ottawa replaced its 2,100-tonne Lees Avenue overpass in a single night. A time-lapse video of the operation went viral.

What does this mean for refurbishment?

Refurbishing Ontario’s nuclear power plants won’t be as fast as replacing an overpass, but the engineering teams will be working with equipment that is well known, operating on principles that are thoroughly understood. This is not experimental, but an upgrade. And the teams taking on the job now have built up a lot of experience on accumulated industry know-how.

To begin with, Bruce Power has already refurbished two reactors. That project showed how the team learned: On the second reactor they refurbished, the team did several tasks much more quickly, replacing the second steam generator 57% faster than the first, and removing the second set of calandria tubes 77% faster than the first. Bruce Power then delivered another life-extension project on one of the reactors on time and budget, in 2011.

In the first refurbishment, the reactors had been offline for 17 years. It was like starting up a classic car that has been sitting in a garage – a really great car, but one that hadn’t been used. The engineers had to find out exactly what state the reactors were in first before going ahead with the overhaul. In contrast, the upcoming Bruce refurbishment is on reactors that are running now, and running well, so much of the planning is already done.

Every activity Bruce Power will have to do on the site is something it has done before. It’s familiar work. The refurbishment activities are focused on two key elements – replacing steam generators and re-tubing the reactor. Every activity needed to complete these has been tested and its scope defined.

Planning is also long underway at Darlington. Ontario Power Generation (OPG) is on track to have all the required regulatory approvals, project contracts awarded, tools tested, staff trained and a detailed schedule and fully committed budget well before the project execution begins in 2016. According to OPG, “After six years of planning, extensive inspections and benchmarking, 40 years of operational and project management experience, and a ground-breaking nuclear training and testing facility … we’re ready for refurbishment.” In that testing facility, there is a full-scale mock-up of a Darlington reactor vault. It’s accurate right down to the exact bend in every pipe, with thousands of components. Every door, light, hallway, and overhead light is replicated. The mock-up will give OPG and contractors a chance to do each of the jobs they expect to do, and make sure they can do them right, before working on the actual reactor.

All systems go

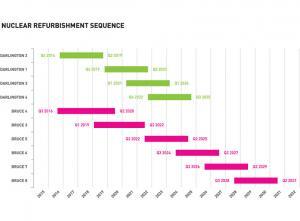

The learning won’t stop once the refurbishment begins. Each system-focused team plans to take lessons from one refurbishment and apply them to the next. That’s one of the reasons why the 10 refurbishments will be spaced over 15 years.

The refurbishments also create opportunities to improve the plants’ systems and materials “while the car hood is up.” At Darlington, in addition to the removal and replacement of reactor components, the refurbishment also involves a tremendous amount of work to maintain, upgrade, and refurbish other important plant systems, such as the turbine and generator sets, fuel handling equipment, and other nuclear, conventional, and safety systems. And because the industry has learned a lot about how materials react to radiation since the Bruce Power station went online, the teams will be replacing some of the parts, such as the fuel channels and steam generators, with materials that are stronger, safer, and longer-lasting.

Finally, the Ontario government has ensured that the contracts will allow it to limit or even stop the refurbishments if they go over budget. That’s a serious incentive for the operators and contractors involved to stay on track.